It’s not all fancy technology and trained pilots — it’s about the dependability of each link in the chain. From the massive motors to the smallest screws, everything has to be just right. Quality airplane parts equal safe flights, working flights, and confidence in aviation. If you don’t get it completely right in every little detail, you can end up with a very expensive, and dangerous, mess.

Key Categories of Aircraft Parts

An airplane is a connected system of thousands of systems. They are roughly divided into:

- Airframe: The positioning of airframes, wings, and body parts to form the shape of the aircraft.

- Mechanical systems: Wheel, brakes, hydraulics, and things that make the aircraft move or fly.

- Avionics: The navigation systems, instruments, and communications equipment that pilots depend on to navigate the sky with maximum safety.

- Cabin and Interior: Seats, emergency equipment, and life-support systems for aircraft occupants.

Understanding these types helps explain why it is so important to manage aircraft parts at every point in the supply chain.

Challenges in Aircraft Parts Supply

There are few challenges in aviation as intractable as maintaining a reliable stock of parts. Typical issues for an airline and maintenance team:

- Global Delays: Bottlenecks in the global supply chain can ground entire fleets.

- Rigid Certification: Whittle down all that raw material through tight certification, to earn the right to make a craft.

- Costly: You pay for fancy materials and production techniques to achieve the look.

- Fake Risk: Unauthorized dealers may send in fake parts.

It’s stories such as these that drive home the importance of always purchasing airframe parts from reputable sources.

Why Trusted Suppliers Matter

It’s about convenience as much as it is about flight safety and efficiency — working with trustworthy suppliers. Some advantages include:

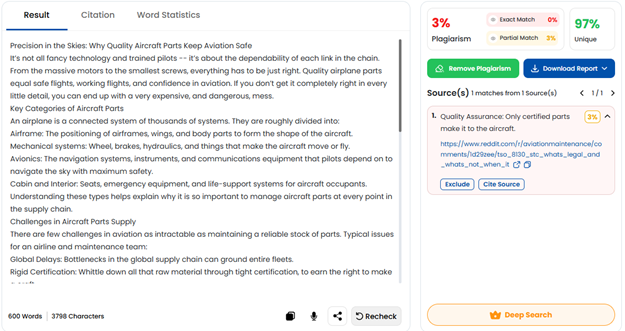

- Quality Assurance: Only certified parts make it to the aircraft.

- Short Downtime: Prompt turn arounds averts delays and cancellations.

- Compliance Free: Never a hiccup during audits or visits.

- Operational efficiency: A few sources means fewer non-essential costs.

The aviation industry does not have the luxury of time to identify which suppliers are appropriate to use — it is the reflection of the dedication to keeping passengers and crew safe.

The Future of Aircraft Parts Truly Networked Management

As aviation and air travel continues to evolve, so too does the process of creating and keeping track of how aircraft parts are made. Here are some of the biggest future trends:

- Blockchain Authentication: This guarantees transparency and does away with counterfeits.

- 3D Printing: For those times when you just want to print something quick and nonessential.

- Eco Materials: No BPA, No Safety concern.

- Predictive Maintenance: AI tells you that X part is going to break before it does.

These technologies are paving the road towards an intelligent, safe, and clean Aviation.

Final Thoughts

In the aviation industry, it is necessary to have strong airplane parts to ensure the safety and functionality of the product. Airlines that invest in robust suppliers and technology innovation can reduce their risk, save costs, and keep their operations going. There’s no compromise in the sky, only precision, reliability, and reliance. Each is another piece of equipment in good working order that contributes to a chain of safety the passengers and crew alike rely on to lift off into the air. As the number of international flights grows, so too does the demand for durable, inventive parts. For the future of flight hangs not only on superlative engineering, but also on the unwavering reliability of all the tiny components that hold the airplane aloft.